021-20232913-8004

Quench tower

Quench tower

The 500℃ gas out from waste heat boiler enters quench tower and directly contacts with spray, which would lead to spray vaporization in just one second. The high-temperature gas lose heat rapidly by heat exchange with the temperature declining from 500℃ to 200℃, which effectively avoid the synthesis of dioxin-like chemicals.

A circle of spray guns are arranged on the upper tapper pipe segment of the quench tower, and the spray direction and the gas flow are in the same direction.

The distribution, velocity and residence time of the gas must be considered in designing the quench tower body.

Tapper pipe form is adopted to control the gas distribution, and there is no deflector in quench tower.

The diameter and height of quench tower are designed according to the amount of cooling water in need, the angle and range of spray gun.

The quench tower consists of inlet, taper pipe segment, cylinder, outlet, taper bottom, manhole, support steel frame and platform, etc.

Lightweight, acid-resistant and insulated casting material should be used inside the quench tower. Refractory material must have good thermal shock resistance, good chemical stability and high acid resistance. And acid-resistant liner should be used in order to ensure the service life.

Spray system

Spray system can automatically track and adjust the spray amount according to the change of outlet gas temperature, ensuring that the outlet gas temperature should be kept in a certain range without over spray or under spray. Under operating condition, the water in the tank flows into the spray guns through the filter, pump and waterway control system, and then the water is atomized into tiny spray droplets by compressed air in the spray guns. The spray droplets evaporated immediately after contacting with the high-temperature gas, absorbing a lot of heat, so the temperature of gas is declined rapidly and kept in a certain range. If the gas temperature is not in the set range, the spray system can automatically adjust the relevant parameters like pressure and spray amount, in order to keep the gas temperature in the set range.

Spray system configuration: spray guns, quenching water pump, control system, steel frame, water lines and air lines.

Electrical control part consists of temperature detection system and program control system.

Spray system includes automatic mode, safe mode and stop mode.

Characteristics of Quenching System

Tiny spray droplets, ensuring the limited evaporation

Compressed air enters the twin fluid nozzles in order to produce tiny spray droplets with the average diameter of about 70µm. Because of the twin fluid nozzles, the quantity of droplets increase for dozens of times with the same water, and the evaporation area increases for several times, so the evaporation time is shorter, and ensuring that there is no over spray.

Larger spray amount, and larger spray area

The spray amount of single nozzle is very large, so the number of spray guns in need is reduced significantly under the same demand, which reduces the workload of installation, repair and maintenance. Any other type of nozzle can’t compete.

The jet diameter of twin fluid nozzle can reach a distance of 3~4m, covering larger spray area, so that the spray can be mixed with the gas more fully, which is conducive to cooling the gas.

Large adjustment range of spray amount, the diameter of spray droplet remains approximately constant

The maximum adjustment ratio of twin fluid nozzle can reach 10:1 by adjusting the pressure of water and compressed air, which could ensure maximum adjustment ability to the change of gas amount and gas temperature. Besides the diameter of spray droplet remains approximately constant within the whole range of spray amount.

The 500℃ gas out from waste heat boiler enters quench tower and directly contacts with spray, which would lead to spray vaporization in just one second. The high-temperature gas lose heat rapidly by heat exchange with the temperature declining from 500℃ to 200℃, which effectively avoid the synthesis of dioxin-like chemicals.

A circle of spray guns are arranged on the upper tapper pipe segment of the quench tower, and the spray direction and the gas flow are in the same direction.

The distribution, velocity and residence time of the gas must be considered in designing the quench tower body.

Tapper pipe form is adopted to control the gas distribution, and there is no deflector in quench tower.

The diameter and height of quench tower are designed according to the amount of cooling water in need, the angle and range of spray gun.

The quench tower consists of inlet, taper pipe segment, cylinder, outlet, taper bottom, manhole, support steel frame and platform, etc.

Lightweight, acid-resistant and insulated casting material should be used inside the quench tower. Refractory material must have good thermal shock resistance, good chemical stability and high acid resistance. And acid-resistant liner should be used in order to ensure the service life.

Spray system

Spray system can automatically track and adjust the spray amount according to the change of outlet gas temperature, ensuring that the outlet gas temperature should be kept in a certain range without over spray or under spray. Under operating condition, the water in the tank flows into the spray guns through the filter, pump and waterway control system, and then the water is atomized into tiny spray droplets by compressed air in the spray guns. The spray droplets evaporated immediately after contacting with the high-temperature gas, absorbing a lot of heat, so the temperature of gas is declined rapidly and kept in a certain range. If the gas temperature is not in the set range, the spray system can automatically adjust the relevant parameters like pressure and spray amount, in order to keep the gas temperature in the set range.

Spray system configuration: spray guns, quenching water pump, control system, steel frame, water lines and air lines.

Electrical control part consists of temperature detection system and program control system.

Spray system includes automatic mode, safe mode and stop mode.

Characteristics of Quenching System

Tiny spray droplets, ensuring the limited evaporation

Compressed air enters the twin fluid nozzles in order to produce tiny spray droplets with the average diameter of about 70µm. Because of the twin fluid nozzles, the quantity of droplets increase for dozens of times with the same water, and the evaporation area increases for several times, so the evaporation time is shorter, and ensuring that there is no over spray.

Larger spray amount, and larger spray area

The spray amount of single nozzle is very large, so the number of spray guns in need is reduced significantly under the same demand, which reduces the workload of installation, repair and maintenance. Any other type of nozzle can’t compete.

The jet diameter of twin fluid nozzle can reach a distance of 3~4m, covering larger spray area, so that the spray can be mixed with the gas more fully, which is conducive to cooling the gas.

Large adjustment range of spray amount, the diameter of spray droplet remains approximately constant

The maximum adjustment ratio of twin fluid nozzle can reach 10:1 by adjusting the pressure of water and compressed air, which could ensure maximum adjustment ability to the change of gas amount and gas temperature. Besides the diameter of spray droplet remains approximately constant within the whole range of spray amount.

Previous:Low-temperature waste heat generation

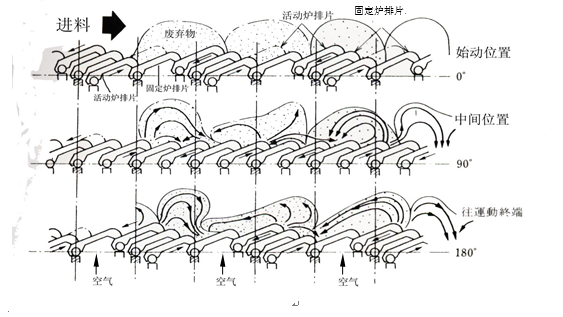

Next:Grate

Related Products:

address:Shanghai City, Putuo District No. 261 Tong Pu Lu (Zhejiang Lucheng - iron Changfeng Center) 15F. Code:200062 Tel:021-20232913*8004 Fax:021-20232911