021-20232913-8004

Grate

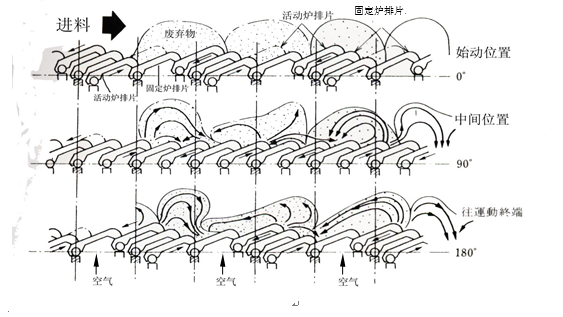

We choose the inclined reciprocating grate with staging air. The combustion process has the character of phase. The slag drop from rotary kiln, moving along the grate from the upper front to lower back, and the air blows from the bottom up to support combustion.

There is relative motion between grate and materials during the reciprocating movement. Some materials with incomplete combustion are pushed up on those with complete combustion when active grate segment move forward, making them burn completely. And when active grate segment move backward, also taking some completely burning materials under those with incomplete combustion and heating them. Materials are continually crushed in the move, destroying the material blocks and ash shells, which make the combustion kernels burn completely. And meanwhile, the constant rolling and turns make the burning materials with more air contact and longer combustion time, preparing for the next reciprocating motion of grate.

Inclined reciprocating grate mainly consists of fixed grate segment, active grate segment, transmission mechanism and reciprocating mechanism, etc.

Diagram of materials movement on the grate

Advantage of adding grate incineration

Adopting our specific technology of rotary kiln incineration combined with tail incineration equipment, which making the residue out from rotary kiln continue to burn to complete combustion on the reciprocating grate by adjusting the movement of grate and air distribution, ensuring the ignition loss <5%.

Advantage of adding grate incineration:

① Reduce the combustion workload of rotary kiln. Some materials with high moisture and ash, low caloric value and poor ignitability, or some materials with incomplete combustion can be continued to be burned with longer combustion time.

② It is easy to effectively control the temperature through adjusting the primary air flow for materials with high caloric value. As a result of adding the grate, partial combustion can be moved on the grate, effectively avoiding the coke phenomena through adjusting the air distribution.

③ Materials can be burned completely with appropriate supply amount of air, and there is low carbon content in the slag, and the ignition loss can be under 5% within the condition.

④ Melting slag and ring formation can be effectively avoided by control the temperature at the rotary kiln terminal through one more air supply.

⑤ The grate is made of heat-resistant alloy steel by casting molding, with maintenance convenience and long lifetime.

There is relative motion between grate and materials during the reciprocating movement. Some materials with incomplete combustion are pushed up on those with complete combustion when active grate segment move forward, making them burn completely. And when active grate segment move backward, also taking some completely burning materials under those with incomplete combustion and heating them. Materials are continually crushed in the move, destroying the material blocks and ash shells, which make the combustion kernels burn completely. And meanwhile, the constant rolling and turns make the burning materials with more air contact and longer combustion time, preparing for the next reciprocating motion of grate.

Inclined reciprocating grate mainly consists of fixed grate segment, active grate segment, transmission mechanism and reciprocating mechanism, etc.

Diagram of materials movement on the grate

Advantage of adding grate incineration

Adopting our specific technology of rotary kiln incineration combined with tail incineration equipment, which making the residue out from rotary kiln continue to burn to complete combustion on the reciprocating grate by adjusting the movement of grate and air distribution, ensuring the ignition loss <5%.

Advantage of adding grate incineration:

① Reduce the combustion workload of rotary kiln. Some materials with high moisture and ash, low caloric value and poor ignitability, or some materials with incomplete combustion can be continued to be burned with longer combustion time.

② It is easy to effectively control the temperature through adjusting the primary air flow for materials with high caloric value. As a result of adding the grate, partial combustion can be moved on the grate, effectively avoiding the coke phenomena through adjusting the air distribution.

③ Materials can be burned completely with appropriate supply amount of air, and there is low carbon content in the slag, and the ignition loss can be under 5% within the condition.

④ Melting slag and ring formation can be effectively avoided by control the temperature at the rotary kiln terminal through one more air supply.

⑤ The grate is made of heat-resistant alloy steel by casting molding, with maintenance convenience and long lifetime.

Previous:Quench tower

Related Products:

address:Shanghai City, Putuo District No. 261 Tong Pu Lu (Zhejiang Lucheng - iron Changfeng Center) 15F. Code:200062 Tel:021-20232913*8004 Fax:021-20232911